The MEC Paver Block Machine enables the production of a wide variety of high-quality concrete landscaping products with fast production cycles and high output volumes. These can be manufactured in different sizes, shapes, and colors, using alternative materials or even two completely different dry cast mixes. Concrete landscaping products are commonly used for constructing sidewalks, driveways, patios, fireplaces, and various other landscape structures.

What is MEC Paver Block Machine?

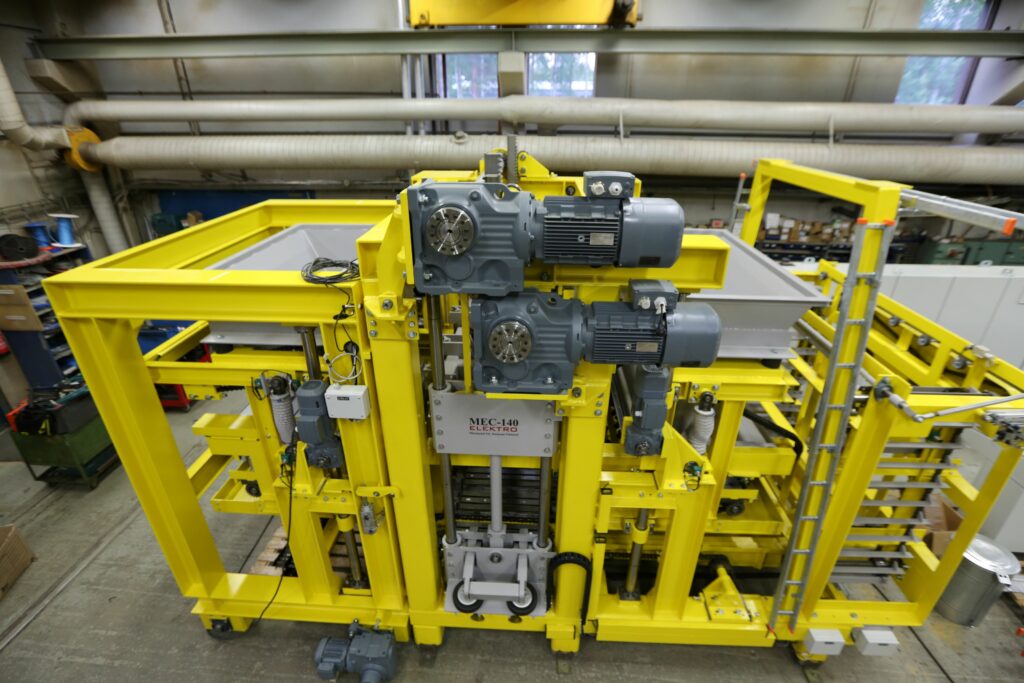

The MEC Paver Block Machine is an enhanced version of the original MEC Evolution-20 block machine. It comes equipped with a Face Mix unit and additional software directly from the manufacturing phase, making it a more cost-effective option for customers compared to retrofitting these features later. Additional equipment for surface treatment—such as washing unit, splitting unit, or antique line—can also be sourced from Mecmetal to create even more product variety.

Market-Leading Efficiency

All MEC Block Machines are fully electromechanical, meaning there aren’t any hydraulic pipes or systems. All movements are powered by electric motors, mainly with powerful and precise servo motors for primary and repetitive movements, such as molding, tamping, and vibration operations. While some AC motors remain in place for practical reasons, everything operates within the same servo control system, making the operation system responsive, smart, and versatile — yet still user-friendly.

The machine’s design is rooted in decades of experience with tested and constantly evolving mechanical solutions. Additionally, new advancements have been developed through active collaboration with customers, addressing the needs of efficient production and market development. Mecmetal has been manufacturing fully electromechanical block machines since 1996

Concrete Intelligence

Our new web-based service is designed to maximize production efficiency and provide rapid responses to any maintenance need or daily help. This innovative solution also offers a wide range of predictive maintenance guidance, real-time diagnostic services and production reporting tools.