Mecmetal Oy specializes in fully electric concrete block machines designed to produce a wide variety of concrete products. These include masonry blocks, landscaping products, and specialized items such as insulated concrete blocks and chimney blocks.

What is MEC Evolution-20 Concrete Block Machine?

The MEC Evolution-20 is the world’s only fully electromechanical concrete block machine, offering a cleaner, more efficient alternative to traditional hydraulic machines. Utilizing advanced servo motor technology, this machine delivers precise control, faster response times, and up to 90% energy savings. Its fully electric design with servo motors eliminates the need for hydraulic systems, reducing maintenance requirements and environmental impact while maintaining superior performance and consistency in every cycle. The upgraded control system further enhances efficiency, making production more streamlined and cost-effective.

Market-Leading Efficiency

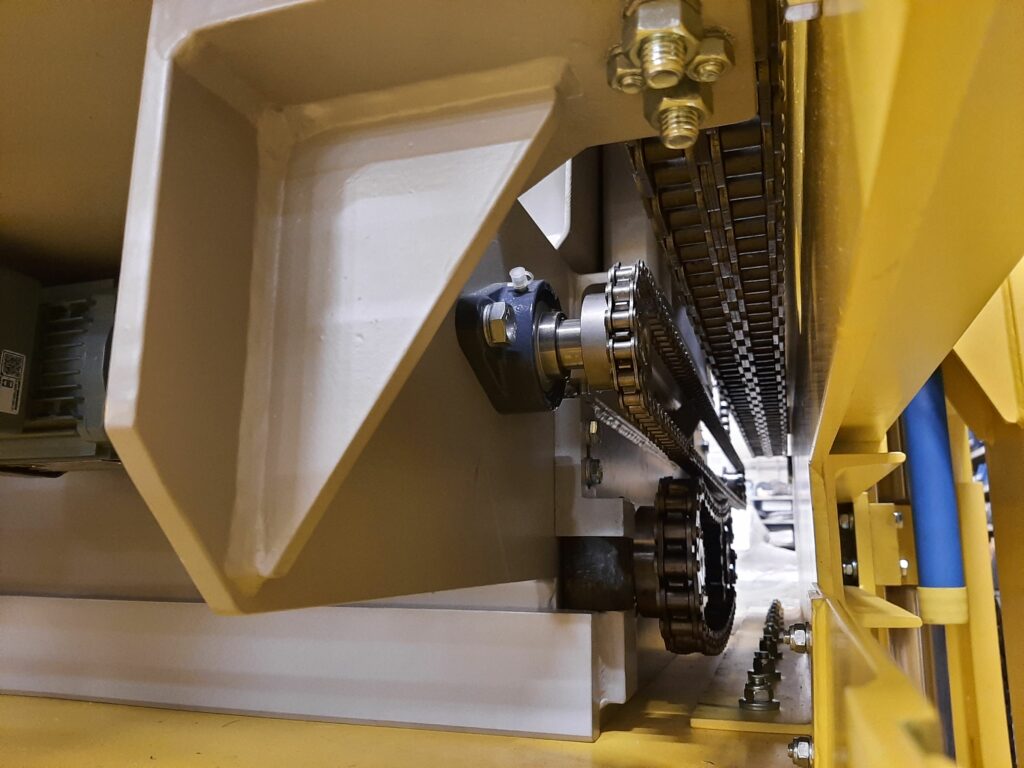

All MEC Block Machines are fully electromechanical, from the block machine itself to every piece of production equipment and attachment. In particular, MEC Block machines are equipped with powerful and precise servo motors, which serve as the primary power source for fast and repetitive movements, such as molding, tamping, and vibration operations. Although some AC motors are still in place for practical reasons, everything is integrated into the same servo control system. Moreover, improved servo gear motor technology guarantees precise and fast movements in all operating conditions and improves energy efficiency to a completely new level.

The machine’s design, from the strong RHS steel frame to the vibration table assembly, is rooted in decades of experience with tested and constantly evolving mechanical solutions. Furthermore, new advancements have been developed through active collaboration with customers, effectively addressing the needs of efficient production and construction material market development.

Concrete intelligence and efficiency

The control system is designed to be both smart and highly versatile, while remaining exceptionally user-friendly and easy to use. As a result, it enables operators to run production efficiently without needing to focus heavily on control system’s technical side. Over time, the system’s versatility becomes a cost-saving factor, particularly when aiming to boost production efficiency for each concrete product in the catalog, all while maintaining the highest product quality. With system’s versatility and stepless adjustments of the top and bottom vibration, as well as the whiskers of the filling car, production managers and operators can easily implement changes to concrete mix recipes, test aggregates, or even develop new products more successfully and at a faster pace.

Additionally, the new web-based services maximize production efficiency and enable quick hotline service to any need, anywhere. These solutions also offer an extensive range of predictive maintenance options and real-time diagnostic services.

See also our other block machine modules for more specific production