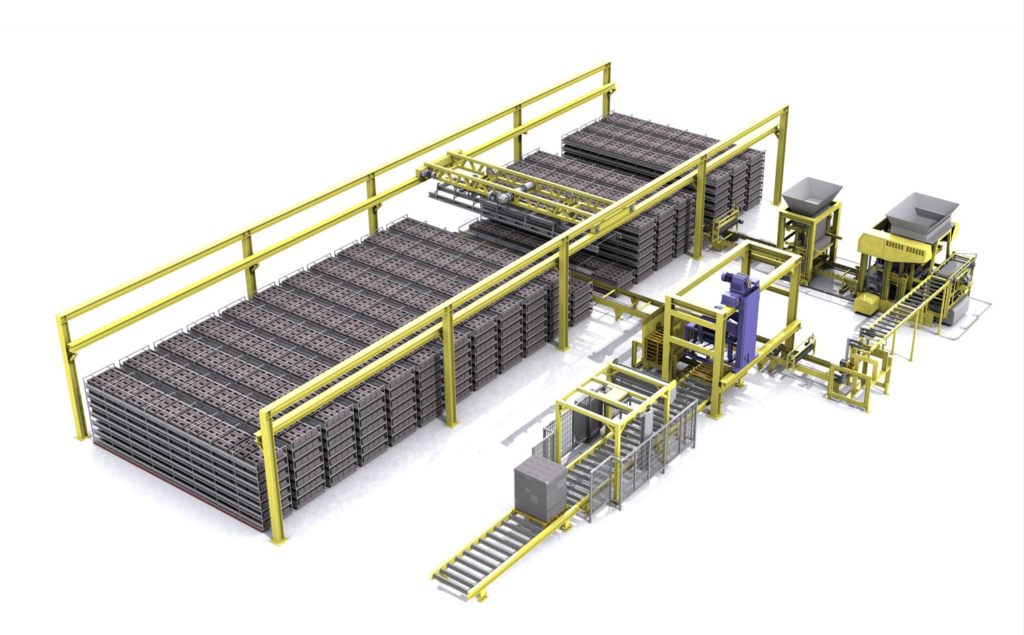

The MEC CRANE includes a fully automatic MEC block machine, a fully automatic handling line with conveyors and crane handling, a fully automatic packaging line and production pallet returner

What is MEC CRANE and how it works?

MEC CRANE is a fully automatic concrete block production line designed to produce masonry blocks, landscaping products, and a variety of other concrete products at high volumes. The production line integrates all stages from block forming to product packaging, excluding the batching plant. The name “MEC CRANE” is derived from the product handling system in the curing chamber, which uses a crane to operate.

MEC CRANE operates similarly to other fully automatic concrete block production lines. The key difference lies in how it handles production pallets in curing chamber. Production pallets, containing freshly molded products, are gathered in a long row. These rows are then lifted as a whole by the crane and moved to the curing area. The crane stacks each row on top of the previous one, using support cages for stability and protection.

MEC CRANE is the ideal solution for production facilities that are short but wide, with curing chamber heights under 6 meters. In cases where the FINGER CAR model is not suitable due to space limitations in the curing chamber, MEC CRANE offers the same level of automation and production handling capacity, making it the best alternative.

Turn-key block production plant

Mecmetal has successfully manufactured and commissioned concrete block plants as turnkey projects globally over 25 years, saving customers time and resources.