MEC-120-ELEKTRO is a concrete product machine with New Generation Technology. The functions of machine are mainly electrically driven and controlled by computer (PC) or programmable logic (PLC). This guarantees exact movements and control of forces in all conditions. The mould recipe automatics always guarantee the same running parameters for every different product after the mould change.

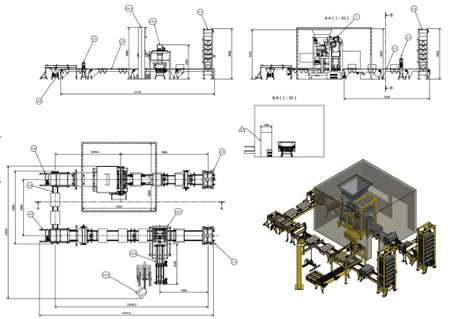

Semi Auto Stacker handling Production line

Used MEC Stacker 1280

Manufactured by Mecmetal in 2012

Advantages

- High utilization rate

- Extremely fault-tolerant

- The manufactured products are very homogenous and high-quality

- Short downtimes

- Long life cycle

- Cost-effective

- Energy efficient

| Technical properties | |

|---|---|

| Fully automatic | |

| Electro-mechanical operation | |

| Accurate tooth gears | |

| Central lubrication system | |

| Directed vibration, frequency and power | |

| Stepless adjustment | |

| Express mould attachment | |

| Bottom face profiles possible | |

| Dimensions | |

|---|---|

| Production pallet size | 1200 mm x 800 mm (production pallets has steel legs for forklift handling, storing and curing ) |

| Product height | 50 mm - 350 mm |

| Machine width | ca. 2600 mm |

| Machine Height | ca. 4400 mm |

| Machine length | ca. 6300 mm |

| Machine weight | ca. 13 000 kg |

More details and features

Machine structure:

- Heavy duty steel profile body. Main FrameRHS 200x200x16 mm beam.

- Guiding of the mold and the tamper by four hardened round bars and changeable glide bearings

- Adjustment of mould height and locking by push button

- Up/down movement of the mold & the tamper by hardened tooth-bars and pair of hardened gear wheels

- The filling wagon moves inside U-beams, guided by four hardened wheels

- The filling wagon movement by the two hardened tooth-bars and the hardened pair of gear wheels

- The filling wagon is provided with a tamper cleaning brush

- The filling wagon is provided with rotating filling activator

- The machine is equipped with “drawing-plate “

The mass cone has rounded inner corners and is provided with a closing hatch. The mass cone is isolated from vibration of the main unit.

Quick-Fix System of the mould:

Fast mould change (if the mix recipe of the product is pre-programmed, mould can be changed in 15 minutes)

- Quick locking of mold

- Mold is fixed with four pneumatic bellows with adjustable pressure

- Quick fixing of tamper by four connectors in a T-groove

Vibration System:

The vibration is implemented with MEC ELEKTRO vibration system consisting of:

- vibration table

- solid rails

- vibrator unit

- electronic vibration power adjustment unit

- four pieces of 4,0 kW electrical motors with frequency converter

Feed:

- Pallet feed onto the vibration table by chain conveyor

- Feed speed is adjustable by frequency converter

- Pallet locking onto the vibration table

Control System:

PC-based MEC ELEKTRO system controls the process together with PLC. PC and PLC located in a dustproof cabinet.

All the movement recipe parameters of each product mold and other production data

(amounts), etc. can be saved into the memory of the control system.

Manual functions of all operations are done using the push buttons.

Reporting:

Following reports are possible to be made:

- production report per product / day / month / year

- paving stone reports by square meter

- kerbstone reports by peace

- mold specific production reports

- fault & disturbance report

Installation:

The actual mechanical and electrical installation of the equipment is performed by the supplier’s installation supervisors and installers. The customer’s representative is responsible for external monitoring of Mecmetal Oy’s equipment during installation. Suppliers installation supervisors do all the work that requires special skills, such as checking connections, setting basic settings and programming automation.

Used MEC Stacker 1280

Please contact for

More information