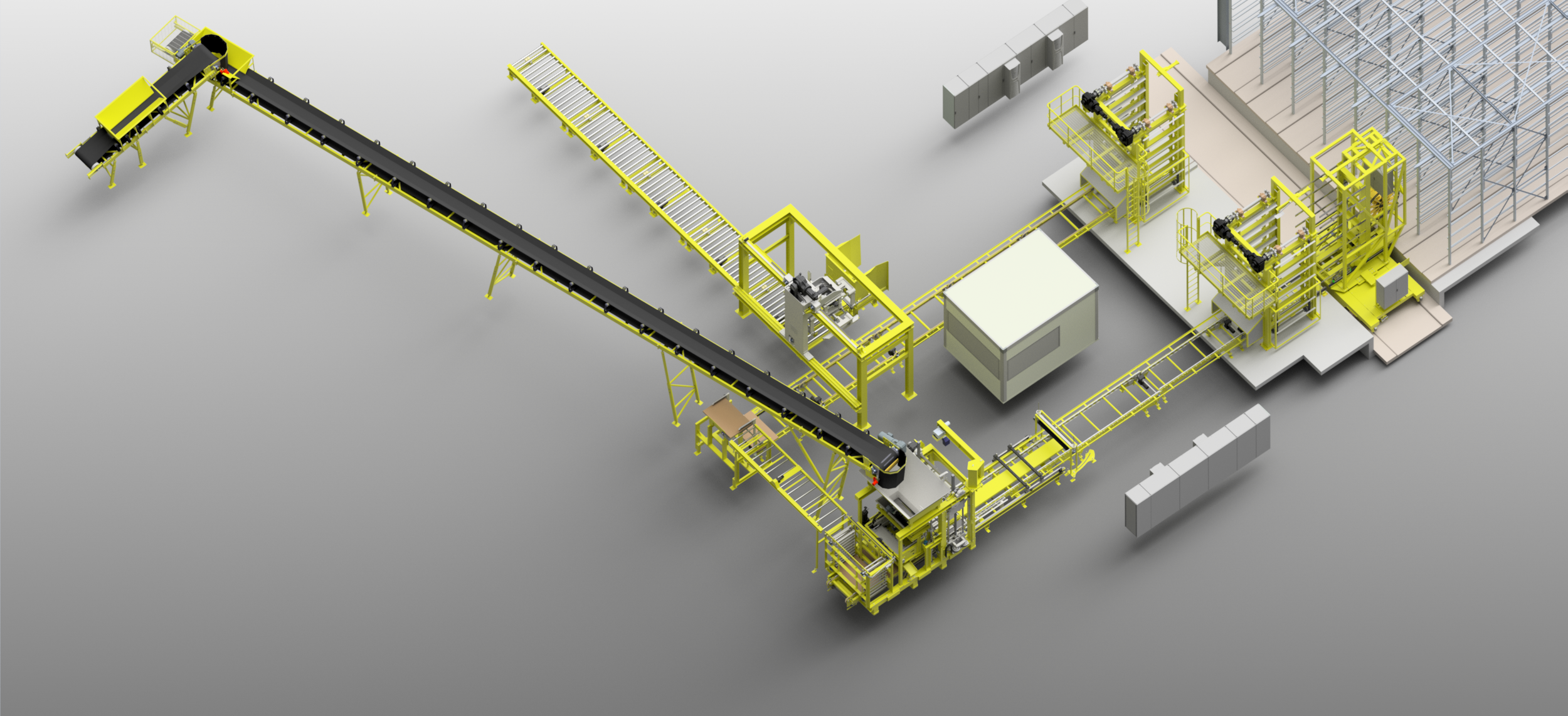

MEC Production lines are used to produce all kinds of concrete masonry blocks, bricks, pavers and other landscaping products as well as products from various alternative materials. All production line models are semi- or fully automated

Designing the concrete block production lines

Our concrete block production lines are always designed in co-operation with the customer. We will help your company to measure your needed production capacity correctly, because the design of a production line is based on a capacity requirement. Main questions should be, how many pallets are planned to be driven in one day, and what size and how many products are planned to be made in one production pallet, this determines the size of the production pallet. After the size of the production pallet, the size of the block machine is determined. Then comes choose of the needed equipment such as a face mix unit, an insulation feeding unit, antique line, split machine etc. After the determination of the block machine and additional equipment, there are optional product handling systems, curing systems and different packaging options.

Now you can build your own production line step by step on our website.

MEC Evolution-20 Concrete Block Machine

Our new generation production lines are equipped with the MEC Evolution-20 concrete block making machine, which is equipped with powerful servo technology as main engines and whole machine is based entirely on electromechanical operations. This operating system makes the MEC Evolution-20 block machine the most accurate, versatile, and energy-efficient block making machine on the market. Components of the block machine and production line are connected to a real-time data collection and monitoring system, which gives instant feedback to operator. Optional MEC web services make it possible to maximize production efficiency as well as enable an extensive selection of services through a client portal.

Long history as a machine manufacturer

In the 1996 Mecmetal developed MEC ELECTRO, a block machine that was solely based on electromechanical operations. It was the first of its kind in the whole world until the release of MEC Evolution-20. MEC ELECTRO was used by our customers to produce a wide variety of different concrete products. What really set MEC ELEKTRO apart from other block machines was it’s accuracy and versatility while maintaining high production efficiency. Many of our customers have sized this opportunity to produce more complex products e.g. insulated concrete blocks and chimneys, gaining bigger market share and great feedback from builders. Ever since the beginning of Mecmetal, we have developed our concrete block machines and production lines to meet our customer needs, from retrofits to whole new facilities

All of our machines and equipment are designed with high requirements by industry experts and manufactured from high-quality materials, to stand decades in the demanding industrial conditions. This, combined with our fast and reliable spare part- and maintenance service, has enabled our machines to have a noticeably long lifespan, average of +20 years, while maintaining same production efficiency and quality. Even the first MEC ELECTRO block machine and production line are still fully in use at concrete factory, southern Finland.

Get to know our block machine and production lines

Fully automated concrete block machine MEC Evolution-20

Fully automated production line with Finger Car handling system MEC FINGER CAR

Fully automated production line with Crane handling system MEC CRANE

Semi automated production line with Stacking system MEC STACKER